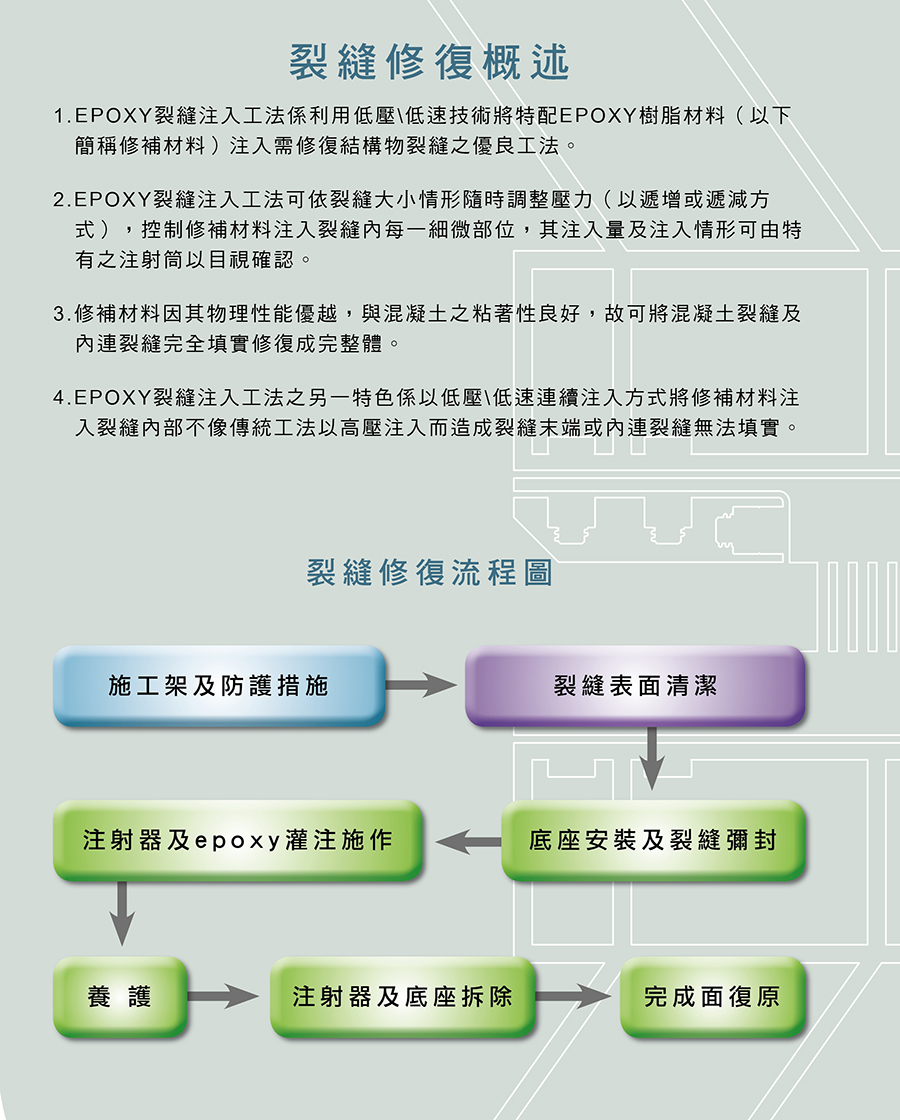

Crack irrigation method

Features

● Crack injection method using low-pressure low-speed technology will be equipped with EPOXY.

● Resin material for the reinforced concrete structures produced by a variety of cracks and cracks in the damage, the need to repair the structural cracks in the fine method.

● EPOXY crack injection method can adjust the pressure (in ascending or decreasing mode) at any time according to the crack size. The control material is injected into every fine part of the crack. The injection and injection can be visually confirmed by the special injection tube.

● Rrepair materials because of its excellent physical properties, and the adhesion of concrete is good, it can be concrete cracks and cracks within the complete fill to complete the whole body.

● EPOXY crack injection method of another feature is low-pressure low-speed continuous note

● The way in which the repair material is injected into the cracks is not like the traditional method of high pressure injection caused by cracks at the end or even cracks can not be filled.

Use

● Filling and filling of bridges, bridges, bridges and bridges.

● Building, warehouse beam, floor, column, wall, retaining wall of the crack reinforcement.

● Groove, warehouse, barn, chimney of the cracks filling.

● Fissures of dams, tunnels, barges and dams.

● Pre-cast, porous cracks in the floor filling.

Example:

SP-868 epoxy crack filling material

Product description

SP-868 low-pressure irrigation material for the low viscosity, room temperature hardening of the epoxy resin crack injection material, is currently widely used in concrete structure crack reinforcement purposes.

Characteristics

(1) No shrinkage - no cracks after filling any cracks.

(2) Strong adhesion - after the completion of the curing will never be split with a split.

(3) Mining low pressure, low speed injection, can effectively inject the number of cracks in every detail.

(4) Impermeable, good durability.

| Use methods and precautions | ||

| (1) | Concrete crack injection surface must first remove the cement hardening layer, floating slurry, grease and other pollutants. | |

| (2) | The first to seal the base and the cracks to be a complete batch of paste and paste, be sure to complete the closure. | |

| (3) | First A and B dose ratio prepared. | |

| (4) | Take an empty bucket into the A agent, stir with an electric stirrer while pouring B agent, stirring about 2 to 3 minutes, stirring evenly after the L-shaped syringe to extract the injection material, and then set in the wall of the base On, to press the way, into the cracks to be pressed to feel the pressure, and then to the rubber ring fixed cylinder pressure can be squeezed slowly. | |

| (5) | Perfusion way from bottom to top, from outside to inside step by step into the injection. | |

| (6) | For safety and health considerations, please wear rubber gloves construction. | |

| (7) | The speed of hardening is controlled by the atmospheric temperature, absolutely can not increase or reduce the amount of hardener mixture to control the hardening speed, change A agent and B mixture ratio will cause hardening, reduce the physical properties of the glue. | |

| (8) | If you accidentally touch the hands or skin, please use a toluene cloth to wipe, and then wash with soap and water. | |

Photo and description:

|

|

|

|

||

|

01-Structural Cracks and |

02-Structural Cracks and |

03-Structural Cracks and |

||

|

|

|

|

||

|

04-Top version of carbon |

05-Top version of carbon |

06-Top version of carbon |

||

|

|

|

|

||

|

07-Structural Cracks and |

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)