Application

1. Construction: steel structure of the foundation, reverse the wall, after playing shock Bi, PC board joints and other grouting.

2. Civil engineering: bridge support pad, base, tunnel back fill, rock plate consolidation, track plate, concrete pits, missing angle, crack repair filling and other grouting.

3. Mechanical engineering: nuclear power plants, pressure steel pipe base and a variety of mechanical equipment base, fixed bolt, bolt grouting.

Characteristics

1. In the low mix of water, with high mobility.

2. High strength, final strength 28 days> 10,000psi / in².

3. Non-corrosive non-chlorinated and metal components.

4. No shrinkage characteristics, improve the size of the safety and mortar bed of the crash and vibration. Materials have been pre-mixed, easy construction, improve project quality, in line with economic requirements.

5. Excellent gradation mix, providing good density and water resistance.

6. Can increase the old and new concrete cohesive force.

Construction procedure1. Construction conditions: concrete surface to be saturated, and the surface can not have water phenomenon.

2. Surface treatment: concrete surface must be stone and clean, no grease, broken pieces and loose the situation.

3. Material mixing: grouting material water consumption can be adjusted according to the required consistency, the general use of the situation as follows: 25kg grouting material to add about 3.7 liters of water. Stir the first about 2/3 of the water into the mixing tank, and then slowly add the filling and start mixing mixer (mixer maximum speed can not exceed 500rpm), while the remaining 1/3 of the water to join. In order to make the material fully mixed evenly, stirring time must be at least 3 to 5 minutes.

4. Application: Mix the sand after the material should be placed at least 3 minutes before use to ensure that the mixing of the material produced by the air completely overflow. The work of the mold must be tight and tight so that it does not leak to avoid loss of the slurry. When the bottom of the base of the water, should avoid the slurry intermittent to re-pour the air to form the bottom of the base uneven grouting and honeycomb phenomenon. Grouting in the large area of water can be applied when the mercury perfusion.

Precautions1. High strength, non-shrinkage cement mortar for grouting special materials.

2. The minimum filling is 10mm.

3. Each grouting maximum thickness of 5 cm, more than 5 cm should be stratified grouting.

4. Construction of the lowest temperature of 10 ℃.

5. Under the temperature of 20 ℃ below the construction of its setting time and strength to achieve a relatively slow.

6. Maintenance of the mortar surface takes at least 3 days (can be maintained using Antusol E curing agent or other means)

7. Large area grouting should be stratified or sub-infusion, and should be added in the grouting material mixed with the use of fine particles, the particle size should be depending on the site conditions, the mechanical base filling the largest particle diameter Not more than 2mm, other ways of perfusion, the particle size shall not be greater than 10mm.

Watering mortar precautions

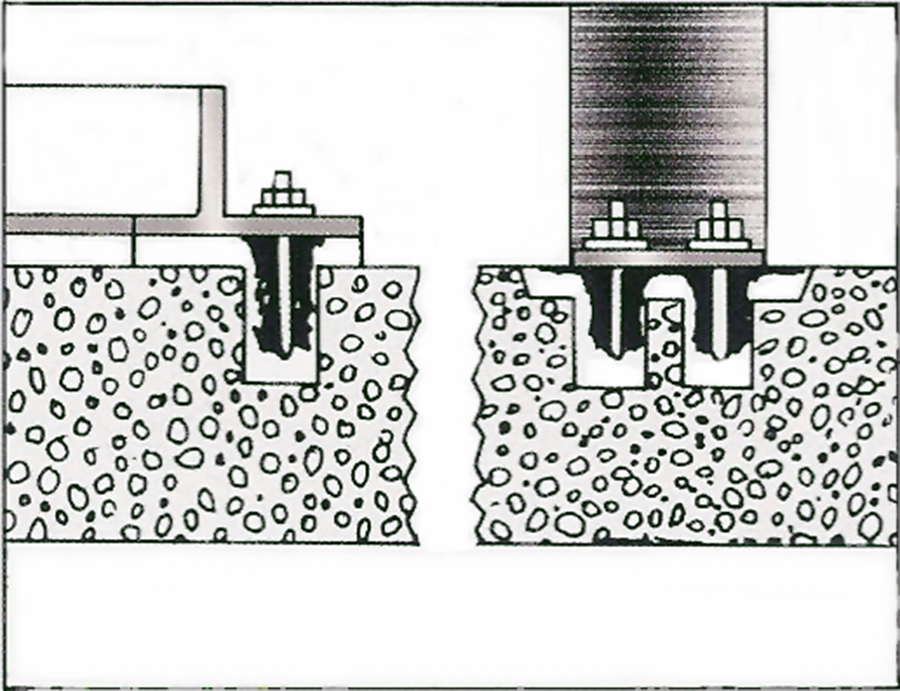

1. Bottom foundation and mechanical foundation of the grouting:

Grouting mortar 24 hours before the first water should be wet water, so that the surface dry state of saturation, the construction surface can not have water situation. Watering should be maintained at a certain level of the head to avoid the re-irrigation of the air, the process of water can be used wire or cable under the base back and forth pull (as shown in Figure 1) to ensure that the bottom of the base of the bubble completely discharged.

.jpg)

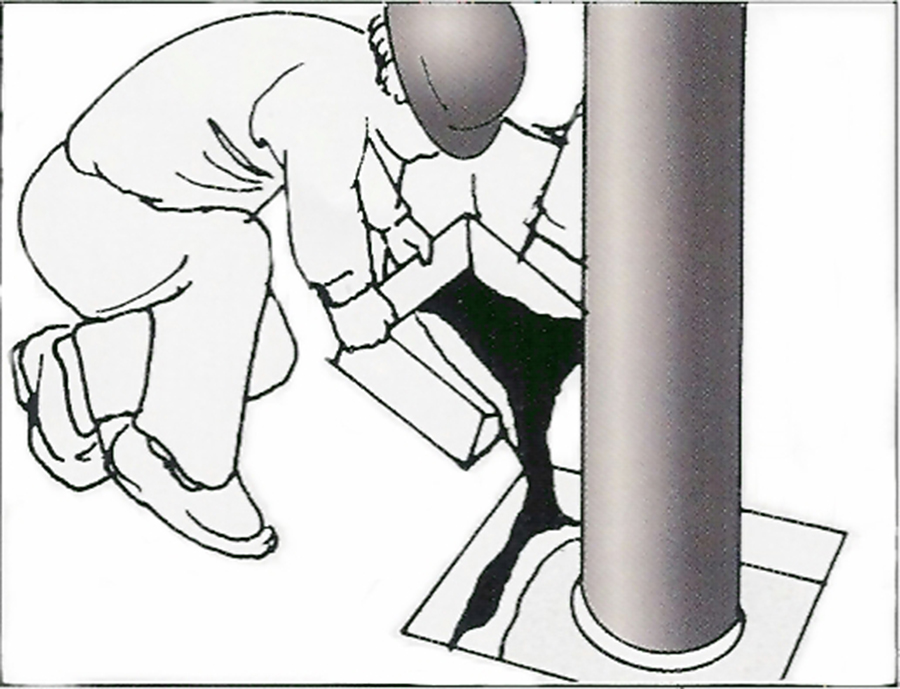

2. Anchor grouting:

Bolt holes and substrates must be watered to reach a saturated state and can not have water phenomenon. In order to ensure the flow of mortar can be the first watering bolts and then pour the base bed (shown in Figure 2). If the coarse aggregate is added to the slurry, the seam shall be at least three times the diameter of the aggregate.

3. Large area of the grouting:

(As shown in Figure 3) filling the mortar when the volume of the pouring to add the size of 10mm below the fine aggregate to meet the economic benefits, fine aggregate and grouting material weight ratio of not more than 1: 1, to ensure that the grouting material Close, should be slightly shaking when placed.

Photo and description:

|

|

|

|

||

|

01-Poor concrete removal |

02-Template group |

03-Templates are complete |

||

|

|

|

|

||

|

04-No contraction of perfusion |

05-No shrinkage perfusion |

06-No shrinkage finish |

.jpg)

.jpg)

.jpg)

.jpg)